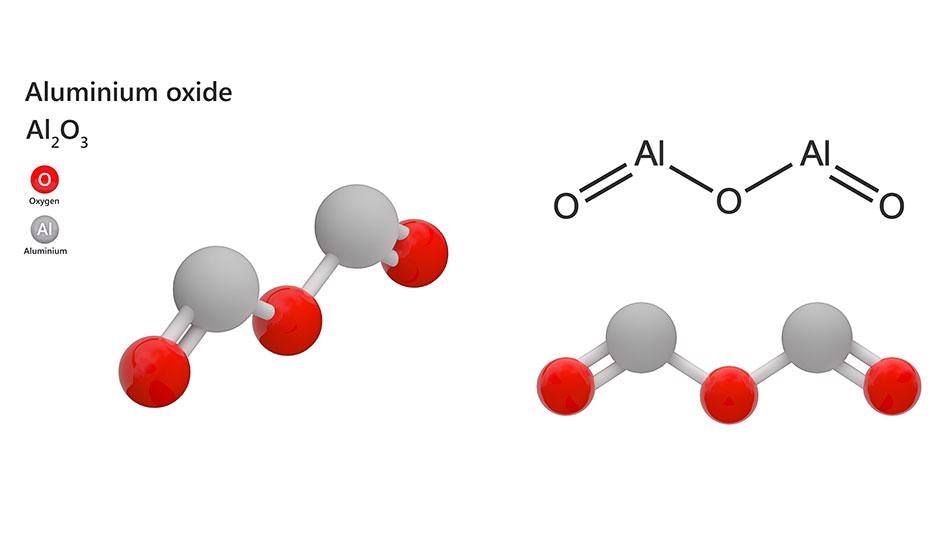

Aluminium oxide iupac name or aluminum oxide american english is a chemical compound of aluminium and oxygen with the chemical formula al 2 o 3 it is the most commonly occurring of several aluminium oxides and specifically identified as aluminium iii oxide it is commonly called alumina and may also be called aloxide aloxite or alundum depending on particular forms or applications.

Al2o3 ceramic applications.

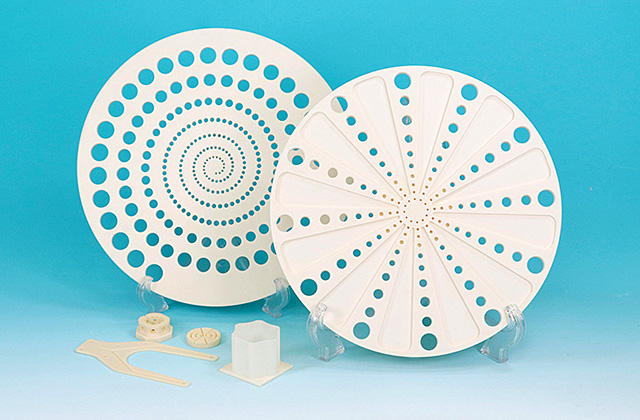

Used for making parts for cvd ion implants photolithography and semiconductor parts.

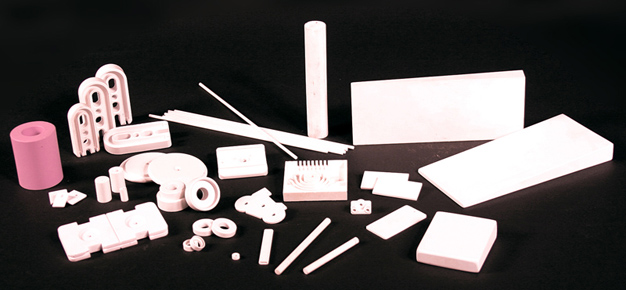

Alumina oxide ceramics al2o3 is the most widely used fine ceramics material.

Alumina or aluminum oxide al2o3 in its various levels of purity is used more often than any other advanced ceramic material.

In traditional industries al2o3 ceramics are ideal for products such as injector tubes gas nozzles and insulators.

This material has superb material characteristics such as high electrical insulation high mechanical strength high wear and chemical resistance.

It has been used for decades in electrical components for its high electrical insulation and is widely used in mechanical parts for its high strength and corrosion and wear resistance.

Ceramtec offers a wide range of material types with different property profiles that can be adjusted via a targeted matrix design.

Aluminium oxide is an electrical insulator but has a relatively high thermal conductivity its hardness makes it suitable for use as an abrasive and as a component in cutting tools.

It has the same sintered crystal body as sapphire and ruby.

It is found in nature as corundum in emery topaz amethyst and emerald and as the precious gemstones ruby and sapphire but it is from the more abundant ores such as bauxite cryolite and clays that the material is commercially extracted and purified.

Aluminium oxide al 2 o 3 or alumina is one of the most versatile of refractory ceramic oxides and finds use in a wide range of applications.

.jpg)